How it works

Learn how NanoGuard Canada’s superior disinfection products prepare surfaces for Pathene™ microbiostatic antimicrobial coating to work and protect you

We use two leading edge products to disinfect the environment and to coat the environment with a 90 day protectant.

Vital Oxide, a hospital grade disinfectant that is Health Canada Certified, Boeing D6-7127 Rev P, EPA Certified, NSF D2 Food Safe, No Rinse Required Surface Contact and a 99.999% 5 log kill reduction.

Pathene™, is a PMRA-Health Canada certified, continuous microbiostatic antimicrobial protectant, that is a safe, green, non-leaching, with no heavy metals, no triclosan and versatile.

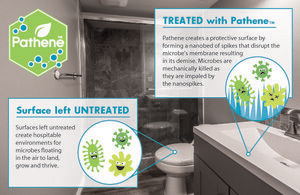

Pathene™ forms a covalent microbiostatic bond to the substrate it is applied to. It creates a protective coating of nanospikes that are positively charged and attract bacteria to them. These nanospikes kill the microbes on contact by piercing the cell membranes. Our coating remains on the surface and actively inhibits the growth of pathogens, mold, mildew, algae and fungus for 90 days!

What Is the difference between this product and other Antimicrobials in the marketplace?

Most commercial antimicrobials used are disinfectants capable of providing a quick inhibition of bacteria and fungi (although some have a limited spectrum of effectiveness). These products penetrate living cells and kill by way of poisoning the organism. They are designed to act quickly and dissipate quickly to avoid adverse effects to humans and animals due to their toxic ingredients. We take a totally different approach. Pathene is a coating which provides a complete initial microbial kill when it is applied, then the coating remains effective for 90 days, providing long-term prevention of microbe growth on treated surfaces.

This means it continuously protects the surfaces between cleaning intervals – when other traditionally cleaned and disinfected surfaces, would be collecting bacteria immediately following the completion of their cleaning.

When surfaces are Pathene™ Protected, you, your family, passengers, students, crew, staff and partners enjoy the same confidence you do as they board your aviation, marine or land-based assets. Other Antimicrobial’s on the market use a poison method to kill the bacteria with chemicals, which leads to the creation of super bug’s and destroys sensitive surface materials. Our methodology is much more environmentally conscious as it does not contribute to the creation of super bugs, does not use heavy metals or VOC’s and will not harm the surfaces of fine aircraft interiors or flight deck components.

After we perform deep disinfection with Vital Oxide all surface are protected with Pathene™ for extended protection, creating sustainably healthy environments.

The AvGuard Protection System

Ensuring the most effective results with our four step process

PREPARATION

-

To ensure a proper baseline test, along with proper disinfection and application, surfaces need to be de-greased of heavy dirt and contamination removed.

-

Following surface preparation, we test for bacteria counts using a Hygenia ATP Luminometer.

-

Assessment of assets and facilities is completed and a tailored solution is prepared.

DISINFECT

-

Using electrostatic sprayers Vital Oxide disinfectant is applied for deep disinfection of all surfaces.

-

The electrostatic sprayer technology ensures the disinfectant will be drawn to hard to reach areas, such as under chairs, desk edges, hidden edges of door handles, buttons, knobs, counter back splashes, instrument panels.

-

Application using electrostatic sprayers reduces human error, avoids missed touch points and prevents wasted product from improper application.

APPLICATION

-

After allowing a drying period of about a half hour, we apply Pathene™ microbiostatic anti-microbial surface protectant for 90 day protection. Disinfecting, regardless of how often you do it, only mitigates the risks of transmission for a small window time after its use. Without a micro-biostatic antimicrobial coating, you’re simply cleaning the surfaces periodically and it is immediately unprotected after. This is the key to sustainably healthier environments.

VERIFICATION

-

We repeat the testing with the Hygenia ATP luminometer to determine the success rate of our disinfection, as verification is critical.

Our testing is performed with Hygenia™

The world’s best selling APT Luminometer